The past few years have been an unexpected yet mandatory crash course in logistics risk management for most eCommerce businesses. From natural disasters to labor strikes to sudden trade rule changes, supply chains have been tested in ways few companies anticipated. What were once rare setbacks have now become part of the everyday operating environment for global commerce.

At ePost Global, we’ve learned that you can’t eliminate disruption. But you can engineer a risk management plan that makes your supply chain operations resilient enough to withstand it. We’ve seen firsthand that businesses that invest in preparation are the ones that keep goods moving while competitors scramble to catch up. And when 23% of eCommerce shoppers say they won’t return to a brand after just one delivery delay, that’s nearly a quarter of your customer base you risk losing if you gamble on “business as usual.”

Risk Isn’t the Exception; It’s the Rule

Supply chain risk is daily business. And while only the biggest shocks make the news, disruption is happening all the time. The following examples reveal the sheer breadth of supply chain setbacks, both the headline-grabbing crises and the delays that rarely make the U.S. news.

- 2020 – COVID-19 Shutdowns: Factory closures in China, Europe, and North America collided with border restrictions to collapse global shipping. Container rates from Asia to the U.S. coasts soared from roughly $4,700 to more than $20,000 per container, draining margins for eCommerce sellers just trying to meet demand.

- 2021 – Ever Given Blocks the Suez Canal: A single container ship stuck for six days jammed a route carrying about 12% of global trade worth $9 billion per day. The blockage delayed thousands of shipments between Asia and Europe and caused ripple effects in inventories worldwide for months.

- 2021 – Global Semiconductor Shortage: Starting with pandemic-era factory shutdowns in Taiwan and Malaysia, chip supply collapsed just as demand for electronics surged. Automakers idled plants in Detroit and Stuttgart, and retailers faced out-of-stocks on laptops, phones, and gaming consoles, showing how upstream shortages hammer consumer sales.

- 2022 – Hurricane Ian in Florida: The storm forced closures of major Gulf Coast ports including Tampa and Jacksonville and stranded thousands of containers. Retail restocks slowed during the critical holiday buildup, and regional trucking networks struggled to catch up.

- 2022 – Pakistan Floods: Record-breaking monsoon rains submerged one-third of the country, wiping out road access to the Port of Karachi. Textile and apparel exports—essential for U.S. and EU retailers stocking seasonal fashion—were disrupted for weeks.

- 2022 – West Coast Port Congestion: At its peak, more than 100 ships sat waiting outside Los Angeles and Long Beach, the main entry points for U.S. imports from Asia. Transit schedules stretched by weeks, and importers paid skyrocketing demurrage fees to keep containers moving.

- 2023 – Canadian Rail Strike: Freight traffic between Canada and the U.S. slowed to a crawl. Retailers dependent on just-in-time deliveries were forced into premium trucking rates to keep goods flowing, cutting directly into already thin margins.

- 2023 – UPS Holiday Volume Caps: During peak season, UPS hit its capacity limits and stopped taking new orders from some customers. Retailers had to scramble for last-minute courier alternatives, leaving many holiday orders delayed or cancelled.

- 2024 – Civil Unrest in Haiti: Port closures in Port-au-Prince forced vessels to reroute to other Caribbean hubs. Transit times stretched by weeks, and costs rose sharply for thin-margin goods, from apparel to agricultural exports.

- 2024 – Canada Post Strike: Rotating walkouts escalated into a nationwide stoppage, leaving more than a million packages stuck in backlogs each day. Black Friday and holiday orders across Canada were delayed, forcing eCommerce sellers to seek costly courier alternatives.

- 2024 – Midwest Blizzards at O’Hare: Severe storms grounded cargo flights in Chicago, one of the busiest freight hubs in the U.S. Critical medical shipments and holiday retail orders alike were delayed, underscoring how weather can cripple supply chains.

- 2025 – HS Code Mandate: Beginning September 1, 2025, every international shipment will require detailed product classification. Businesses that fail to comply risk costly delays, returns, and dissatisfied customers.

And these aren’t the only threats. Financial shocks—sudden tariff hikes, volatile fuel pricing, currency swings—can squeeze margins just as quickly as a port strike. And while less visible, cybersecurity failures or targeted attacks on logistics software can paralyze tracking systems, delay customs filings, and ripple across entire supply chains.

You might think you needn’t worry about events that occur far away, but global supply chains are so tightly connected that distance doesn’t shield you. A factory shutdown in Asia can leave your U.S. warehouse empty. A weather event in the Caribbean can bump your cargo down the line as carriers reshuffle capacity. Policy decisions in Brussels or Washington can change duties overnight, leaving your customers footing surprise costs.

That’s the ripple effect. Disruptions don’t always stay local. And for eCommerce businesses, the impact shows up fast with higher shipping bills, inventory stuck in limbo, and frustrated customers who don’t care why their order is late, only that it is.

The lesson is clear: Global events may happen on distant shores, but the fallout lands in your checkout cart.

The Cost of Being Unprepared

Every failed or delayed delivery carries a price tag. In the U.S., nearly 1 in 10 first delivery attempts fails, costing retailers an average of $17.20 per package. For a midsize brand, that’s about $200,000 a year gone before you even count refunds, reships, or expedited fixes. And the real damage runs deeper.

- Customers don’t forgive easily. Studies show that even one late package can shake trust, but when delays happen more than once, more than half of shoppers cut ties for good.

- Slow shipping kills sales before they even happen. Roughly 23% of online shoppers abandon their carts the moment they see long delivery timelines. No amount of marketing spend can make up for a checkout experience that signals “you might not get this on time.”

- Your reputation takes a hit. Word spreads fast. Negative reviews about missed deliveries or surprise delays drag down conversion rates and make it harder—and more expensive—to win new customers.

And the stakes climb during peak seasons. Imagine launching a holiday product line, only to have a port strike push shipments back two weeks. Suddenly your must-have gift shows up in January, you’re forced to slash margins in clearance sales, and the buzz you built disappears overnight.

Logistics risk isn’t an internal headache—it’s a customer-facing issue. Get it wrong, and you lose sales, loyalty, and reputation in one shot.

Building a Risk-Resistant Logistics Strategy

Risk is inevitable, but it doesn’t have to derail your supply chain operations. Effective risk management strategies take a proactive approach: anticipating potential disruptions, building contingency plans, and setting up systems that allow you to pivot fast when the unexpected happens.

1. Diversify Carrier Networks

Relying on a single provider creates a single point of failure. Strikes, service outages, or capacity crunches can freeze logistics operations at the worst possible time. A diverse carrier network builds resilience into supply chain operations, ensuring that a breakdown in one lane doesn’t cascade into missed orders or customer frustration. It’s the foundation of effective risk management strategies and business continuity.

2. Expand Fulfillment Footprints

Centralizing inventory in one warehouse looks efficient on a spreadsheet, but it magnifies vulnerabilities. A hurricane on the East Coast or wildfires in California can shut down entire regions. With multiple fulfillment nodes, sellers can reroute orders quickly and maintain smooth operations even when natural disasters or regional breakdowns hit. This proactive approach helps mitigate risks and protect customer satisfaction.

3. Flexible Transportation Routes

Delays at borders or ports can snowball quickly, turning a small holdup into weeks of disruption. Without contingency plans, a single chokepoint might derail an entire season. Building alternate routes keeps goods moving and maintains operational efficiency. The goal isn’t speed for its own sake; it’s to give logistics operations the agility to adapt when potential disruptions arise. Businesses that plan ahead with flexible lanes protect business continuity and safeguard delivery times.

4. Strategic Inventory Buffering

Maintaining a lean inventory reduces costs, but it also increases exposure to shortages. A two-week safety buffer on top-selling SKUs can prevent stockouts during peak season and preserve margins when demand spikes. Modern inventory management systems, powered by predictive analytics, make it possible to forecast demand shifts, optimize reorder points, and balance vulnerabilities without creating excess.

5. Transparent Partner Communication

Effective partnerships go beyond rates and contracts. Regular risk assessments, audits, and real-time updates with providers and stakeholders help identify potential risks before they escalate. When information flows openly, partners can address vulnerabilities quickly. Without that visibility, businesses are left reacting to surprises rather than preventing them.

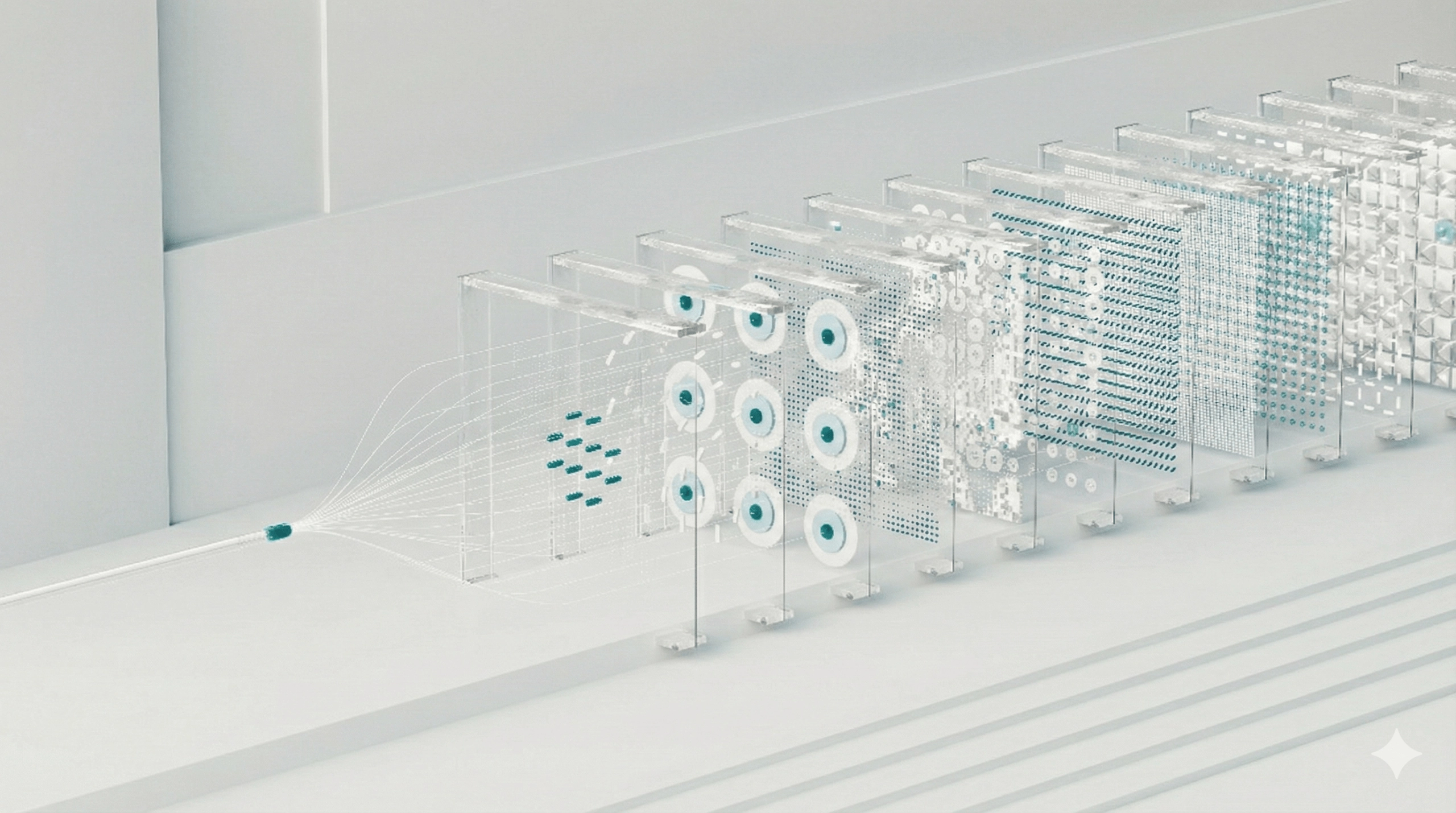

6. Technology As a Risk Management Tool

Technology has become the backbone of logistics risk management. Near-real-time tracking and supply chain visibility tools flag problems as they unfold. Predictive analytics and machine learning algorithms forecast demand changes and optimize decision-making, while IoT devices monitor shipments in transit and highlight breakdowns instantly. The result is a risk management process that allows businesses to act on informed decisions instead of guesswork.

Risk Management Isn’t a One-and-Done Process

Effective supply chain risk management isn’t a set-it-and-forget-it exercise. It’s an ongoing process of continuous improvement. Markets shift, seasons change, and geopolitical tensions evolve, creating new potential risks that didn’t exist a few months earlier. Leading companies conduct quarterly risk reviews, using metrics such as delivery times, carrier performance, and incident frequency to spot weak points before they turn into full-blown disruptions.

Annual “stress tests” for your workflows can reveal how well your business operations hold up under simulated crises, from natural disasters to sudden carrier breakdowns. These exercises are all about building supply chain resilience so that you can make informed decisions when the unexpected happens. The biggest hidden threat isn’t a specific event; it’s complacency.

How ePost Global Helps Businesses Stay Resilient

Running an eCommerce business already demands full attention. Layering on the constant need to track risks, monitor regulations, and build contingency plans can quickly become overwhelming if you’re on your own. That’s why having a trusted partner matters.

At ePost Global, we know eCommerce businesses don’t have room for trial and error when it comes to logistics risk management. Our risk management process is built to absorb supply chain disruptions before they derail your business operations.

Our multicarrier network gives sellers built-in diversification without the hassle of juggling multiple providers. If one carrier hits capacity or external factors slow down a lane, we can immediately pivot through another partner to keep orders moving. That flexibility streamlines decision-making and protects both delivery promises and margins across your entire supply chain.

We also use data to sharpen risk identification. Our tools combine near-real-time tracking, predictive analytics, and machine learning models to flag potential risks early. Instead of reacting after breakdowns occur, you can forecast demand shifts, optimize procurement routes, and mitigate risks before customers ever feel the potential impact.

Equally important is communication. Our teams work directly with stakeholders on contingency plans, so when vulnerabilities surface, you have a clear path forward. That proactive approach ensures smooth operations and gives you supply chain visibility even in the face of complex disruptions.

With ePost Global, managing risks is part of every shipment. By weaving risk mitigation strategies into each stage of logistics operations, we help businesses build supply chain resilience, maintain customer satisfaction, and keep goods moving no matter what comes next.

Make 2025 the Year You Stop Playing Catch-Up

Risk will always be part of global trade, but you decide whether it becomes a disruption or just a speed bump. The right risk management plan strengthens supply chain resilience, keeps your customers happy, and protects your bottom line.

If you’re ready to turn potential disruptions into manageable events, now’s the time to act. Connect with ePost Global to review your current supply chain risk management strategy, identify vulnerabilities, and build a system that can adapt, recover, and keep your goods moving.

The past few years were the crash course. This is the year to graduate, and with ePost Global, you don’t have to take the test alone.

FAQ: Supply Chain Risk in 2025

Why is supply chain risk higher than ever?

Global trade is moving faster and facing more external pressures than in the past. Shifts in tariffs, labor disputes, extreme weather, and carrier shortages mean there’s no such thing as “business as usual” anymore. Companies that once saw disruption as rare now face it as a constant factor in their operations.

What happens when businesses don’t plan for disruption?

The immediate impact is missed delivery windows, unexpected costs, and unhappy customers. But the longer-term damage often shows up in customer relationships and brand reputation. One shipment delay can lead to lost loyalty, negative reviews, and reduced future sales.

How can businesses build resilience into their supply chains?

The most effective strategies spread out risk instead of concentrating it. That might mean diversifying carriers, splitting inventory across regions, or building in safety stock for high-demand items. Technology also plays a role. Near-real-time tracking, predictive analytics, and automated rerouting help businesses stay ahead of disruptions rather than chase them after the fact.

Why does choosing the right logistics partner matter?

Because even the best internal planning has limits. A logistics partner with global reach, multicarrier relationships, and visibility tools can bridge those gaps. At ePost Global, we help businesses prepare for the risks they can’t predict, so disruptions become manageable events instead of costly crises.

What should companies focus on in 2025 to stay competitive?

Speed and reliability will define winners and losers. Customers expect orders to arrive on time no matter what’s happening in the world. The businesses that invest in proactive risk management now—backed by partners who can pivot quickly—will not only avoid costly setbacks but also gain an edge in customer trust and market share.